While the past of car parks is one of utilitarian design and a lack of safety consciousness, the future is one of a design-, people- and environmentally-centric approach. As more and more Australians are moving into the inner cities, the need for functional yet aesthetic multi-story car parks is increasing, and with it the requirement for cost- and time-effective manufacturing and implementation.

Here, we're going to consider traditional car parks and their limitations, followed by an outline of what the car parks of tomorrow will look like, and how such structures are orchestrated through Locker's service offerings.

The Problem: The Past of Car Parks

Traditional car parks come with a handful of concerns for its users and the community it's placed in, including poor safety, ventilation and aesthetics.

Poor safety

The inadequate safety measures of traditional car parks are generally manifold. The close proximity of vehicles and pedestrians has led to many accidents, while a lack of adequate lighting and signage can create hazardous conditions — particularly at night time. Additionally, subpar barrier structures which lack functionality and fail to protect both vehicles and pedestrians are commonplace.

Poor ventilation

Tied in with the abovementioned poor safety — and less commonly known — is the often inadequate ventilation systems of traditional car parks. This lack of ventilation leads to the accumulation of hazardous pollutants potentially leading to respiratory problems for both car park users and those who live close by.

This problem is further exacerbated by mechanical ventilation's reliance on electricity, making mitigatory measures expensive, specifically for multi-story car parks.

Poor aesthetics

Many traditional car parks are utilitarian in nature — function over form. Their design is often uninspiring, resemblant of concrete boxes that lack visual appeal. And notably, dull and monotonous exteriors, lack of structural innovation and an overall lack of visual appeal have a negative impact on the car parks surrounding environment. Such monotonous repetition of concrete structures, absence of natural elements and the lack of creativity has shown to contribute toward a sense of communal sterility and dreariness.

While function over form may have been a cost-effective option in the past, it has become increasingly clear that the drawbacks of such an approach are not merely superficial, but rather have tangible implications on public health, environmental sustainability and the overall quality of a region. The priority of cost-effectiveness is being addressed, however, with manufacturers — through the use of innovative technologies and manufacturing processes — now focusing on creating car park facades that prioritise safety, ventilation and ethics without compromising on affordability.

The Solution: The Future of Car Parks

The car parks of tomorrow are visually pleasing, environmentally conscious and safe. Such efforts are made possible through state-of-the-art manufacturing processes and technologies that facilitate bespoke car park facade solutions at a cost-effective rate.

Enhanced aesthetics

While multi-story car parks exist to offer a service that addresses densification through the integration of vital transport infrastructure, that's not to say that these service offerings can't be accompanied by visual appeal.

Designers and manufacturers are increasingly creating contemporary car park facades which are not only functional, but also complement the surrounding streetscape. They also work to consider how the surrounding environmental context may change over time and orchestrate the car park facades accordingly.

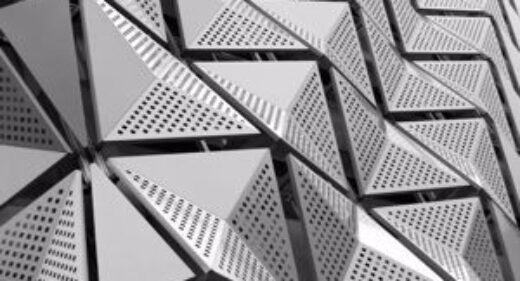

The increasing capacity for creativity and design-centric manufacturing has led to a handful of innovative facade solutions: green walls, living walls, solar panels and perforated metal screens among them. Artwork is also commonly used to add character to car parks, particularly in the context of exploring and expressing a region's history and indigenous heritage.

Enhanced environmental outcomes

Optimally designed car parks incorporate screens and/or other related enclosures that limit the amount of light pollution emitted from the facility, minimising the impact on the surrounding area. These efforts — via bespoke design solutions — don't diminish the visibility of the car park, allowing for the entry of natural light and in turn the reduction of artificial light reliance.

Enhanced safety

Safety remains at the forefront of contemporary car park facade solutions, ensuring the protection of drivers and pedestrians alike. Efforts in this area include the implementation of materials that are not only durable and corrosion-resistant but also incorporate safety features — such as slip-resistant surfaces and fire-retardant properties, among others.

Safety is further prioritised through car park facade providers offering safety management, quality assurance and end-to-end project management, alongside other safety-ensuring services. Locker is one such provider. We offer our clients expert and innovative multi-story car park facade solutions — from design and engineering to manufacturing, implementation and ongoing support/maintenance.

Our multi-story car park facade solutions include two approaches: our Aurora System and Atmosphere System.

Aurora System: A highly customisable cassetted system that is compatible with any substrate of expanded or perforated metal. As the only offering on the market that is capable of crash rail system integration, this system allows for optimum airflow, safety and functionality — paired with its aesthetic appeal.

Atmosphere System: A lightweight, sustainable facade system that is suitable for both retrofitting and new construction. This system features perforated elements that are able to be tailored to the specific requirements of a project, and offers a streamlined installation process via patented tension cable fixing systems.

You can learn more about both systems by clicking here. Or, to learn more about the full breadth of our car park facade service offerings, click here.

With a history of manufacturing excellence, we offer our clients bespoke, high-quality and locally derived facade manufacturing and implementation services that are tailored specifically to your needs. Learn more about how our services can be personalised to your project needs by reaching out to a Locker team member today.